Manufacturing & Industrial

Increase Yields, Improve Quality, and Bring Products to Market Faster with Data Driven Manufacturing Solutions

Featured Industry

- Our Manufacturing & Industrial Solutions

- Improve Quality

- Develop New, Sustainable Manufacturing Methods

- Predictive Analytics for Manufacturing

- Identify Inconsistencies in Production

- Predictive & Preventive Maintenance

- Increase Production Yields

- Training for Manufacturing

Our Manufacturing & Industrial Solutions

With Minitab, you can improve quality, increase production yields, and bring products to market faster. Our solutions can predict changes to your process or fluctuations in demand to eliminate problems before they occur. And that means you can prevent downtime and reduce defects!

With Minitab’s wide array of solutions for manufacturing, we can help you get started on improvement projects or partner with you for digital transformation initiatives.

Improve Quality

For over 50 years, Minitab has been the market leader in quality analytics for manufacturing and industrial organizations. Improving quality can be achieved using a variety of quality tools which can be found in Minitab Statistical Software, Minitab Workspace, and across Minitab's solutions.

Develop New, Sustainable Manufacturing Methods

Learn from Signify (formerly Philips Lighting), the world's leading lighting manufacturer, and get best practices for developing new manufacturing methods. Harness the power of data to demonstrate that recycled materials or 3D printing will make reliable products, including measuring time to failure.

Identify Inconsistencies in Production

Learn how we helped a leading steel manufacturer identify inconsistencies in manufacturing and implement quality controls, which led to improved performance. Using the DMAIC methodology, the project team studied their wire-making process and improved the cooling process at the Laverton Rod Mill. The operators now have better control of laying head temperature, and Minitab analysis confirmed that the improved cooling process has significantly reduced rod scale weight.

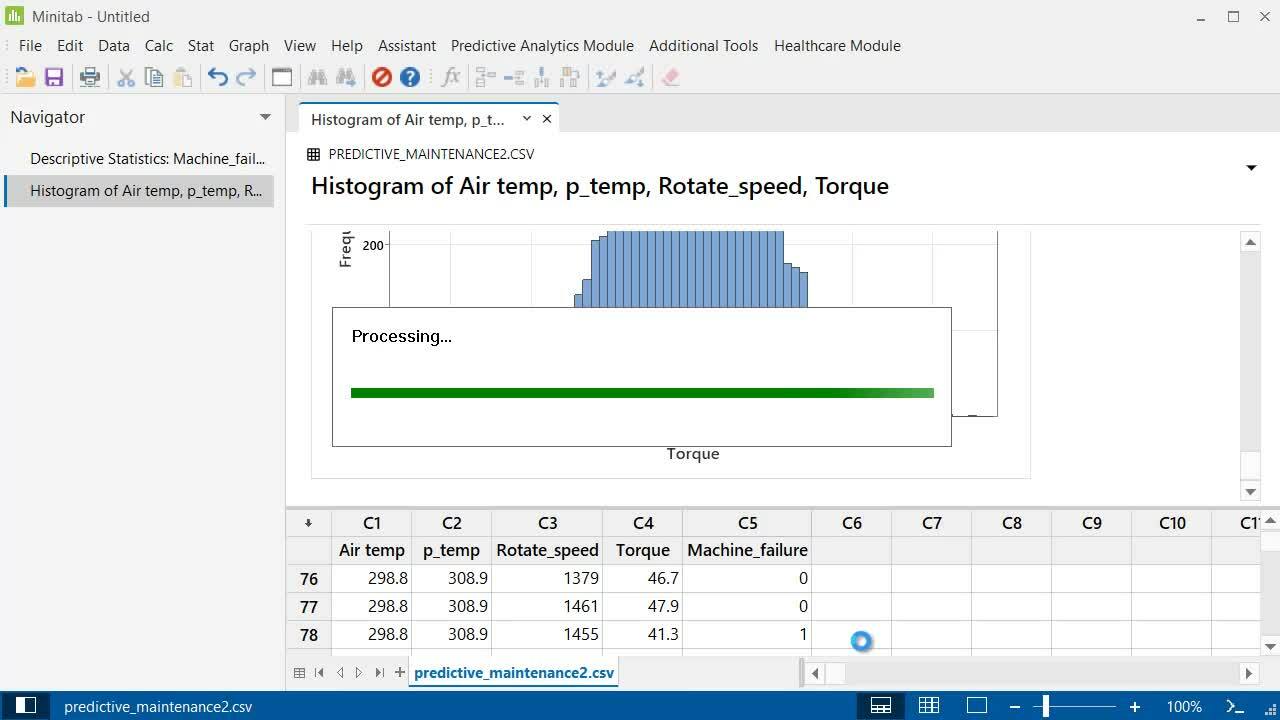

Predictive & Preventive Maintenance

Predictive and preventive maintenance begins with understanding the reasons behind equipment failures. Using Minitab solutions, insight into these failures is available with a click of a few buttons. Get enabled to build your own predictive and preventive maintenance program!

Mikhail Golovnya, Senior Advisory Data Scientist for Minitab, shares how to use Minitab solutions to predict machine failure.

Solving Your Daily Challenges to Improve Quality, Reliability, and Production

We know the manufacturing industry faces many unique challenges. Beyond the day-to-day manufacturing process itself, keeping the facility’s machinery running, and inventory at optimal levels is critically important. Plus, you now have to worry about the new landscape of supply chain issues. It’s a lot to manage!

Only Minitab enables you to address all these challenges within one market-leading ecosystem.

Our solutions give you the power to:

- Collect your data automatically, or allow operators to manually enter data so you can monitor your processes in real-time.

- Act without sacrificing a single lot when alarms alert you to defects as they occur!

- Analyze your findings to make improvements and trust predictions to catch problems in your manufacturing process or machinery before they occur.

DID YOU KNOW?

90% of the Fortune 100 use Minitab solutions!

OUR CUSTOMERS

“What I really appreciate about Minitab is that I am able to teach my team how to use it, that they can use it, that they can use the various easy buttons as it were in Minitab to get the data and what that means.”

Erik Sherburne

Advanced Molding Technologies

Quality Manager